In construction and infrastructure maintenance, ensuring the longevity and stability of structures is paramount. Structural strengthening techniques play a vital role in extending the lifespan of buildings, bridges, and other crucial infrastructure. Among the various methods available, cement grouting stands out as a reliable and effective solution. At Risansi Industries Ltd, we understand the critical role that high-quality equipment plays in successful grouting projects. That’s why we focus on providing top-tier cement grouting pumps, including robust Screw Pumps, to meet the diverse needs of our clients. This blog will explore five key advantages of using cement grouting pumps in structural strengthening, highlighting why they are an indispensable tool for any project demanding precision and durability.

1. Enhanced Structural Integrity and Stability

The primary goal of structural strengthening is to reinforce weak or damaged elements, thereby preventing further deterioration and potential failures. Cement Grouting Pumps play a crucial role in achieving this by accurately injecting grout into voids, cracks, and gaps within the structure. This process, often referred to as cement injection, fills these spaces, creating a solid, homogenous mass that adds significant strength and stability. Whether used to repair foundation cracks, reinforce concrete slabs, or stabilize masonry walls, the precision afforded by a cement grouting pump ensures that the grout reaches all critical areas, effectively distributing loads and preventing further structural movement. The result is a structure restored to or surpassing its original design strength.

2. Precise and Controlled Grout Injection

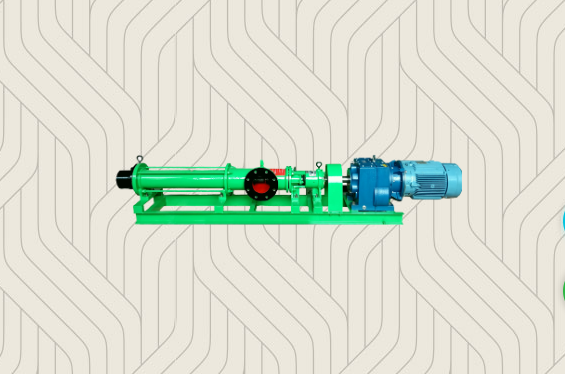

One of the most significant advantages of using a cement grouting pump is its ability to deliver grout with precision and control. Unlike manual application methods which can be inconsistent, a pump ensures that the grout is mixed properly (with suitable flowability) before being injected at a controlled rate and pressure. This control helps prevent issues such as over-injection, which can cause further damage to the structure, or under-injection, which might leave voids, impacting the overall repair. Screw Pumps, in particular, are known for their consistent delivery rates and minimal pulsation, making them ideal for delicate grouting applications where precision is paramount. For a business looking for a reliable screw pump manufacturer, Risansi Industries Ltd. offers specialized solutions designed for consistent results.

3. Cost-Effectiveness and Time Savings

Compared to extensive rebuilding or replacement of damaged structures, cement grouting is a highly cost-effective alternative. Using a cement grouting pump can significantly reduce labor costs and project timelines. The efficiency and precision of these pumps mean that less grout is wasted, and the application process is much quicker than manual methods. These factors translate to substantial savings and reduced disruption, making grouting a cost-conscious choice for both repair and preventive maintenance. Furthermore, the extended lifespan of the strengthened structure reduces the likelihood of future repairs, leading to long-term cost benefits.

4. Versatility for Diverse Applications

From bridge maintenance to tunnel lining and residential foundation repairs, cement grouting pumps are remarkably versatile. They can handle various grout mixes, including cementitious, epoxy, and chemical grouts, making them suitable for a wide range of applications. They are used effectively for soil stabilization, void filling, rock bolting, and waterproofing, enhancing the structural integrity of a diverse range of projects. Cement Grouting Pumps can be easily adapted to different project needs, confirming their adaptability and value in the industry. At Risansi Industries Ltd, we offer a range of pump models to cater to different application requirements, guaranteeing an appropriate fit for every project.

5. Access to Hard-to-Reach Areas

Another significant advantage of using Cement Grouting Pumps, especially those equipped with specialized nozzles and attachments, is the ability to access hard-to-reach areas. These areas, often inaccessible by other methods, can be effectively treated using a pump system. Whether it’s a narrow crack in a concrete beam or a void beneath a building foundation, a cement grouting pump with the right nozzle can deliver grout with high accuracy, ensuring complete and effective repair. This ability to reach critical areas is particularly valuable in complex structures where manual grouting is physically impossible or impractical. For large sites with a gradient, a good Slop Pump is a must have to help with the flowability of the grout.

Conclusion

Cement grouting is an efficient and versatile method for achieving structural strengthening, and the use of a quality Cement Grouting Pump is essential for optimal results. At Risansi Industries Ltd, we are committed to providing our clients with highly reliable and performance-driven solutions. Whether you need a robust Screw Pump, or a specific design model, our pumps are engineered to meet the most demanding applications. The advantages of precision, speed, cost-effectiveness, versatility, and the ability to reach difficult areas make cement grouting pumps essential tools for any construction project aiming for lasting structural integrity. By choosing the right equipment, you can ensure the longevity and safety of your structures for years to come.