Introduction

The Europe Iron Ore Pellets Market is witnessing robust growth due to the rising demand for high-quality steel, the ongoing decarbonization of the steel industry, and technological advancements in pelletizing processes. Iron ore pellets, formed by agglomerating and indurating fine iron ore particles, are essential feedstock for blast furnaces and direct reduction processes. With Europe’s increasing focus on green steel production, energy efficiency, and emission reduction, the demand for iron ore pellets with higher iron content and lower impurities is steadily rising.

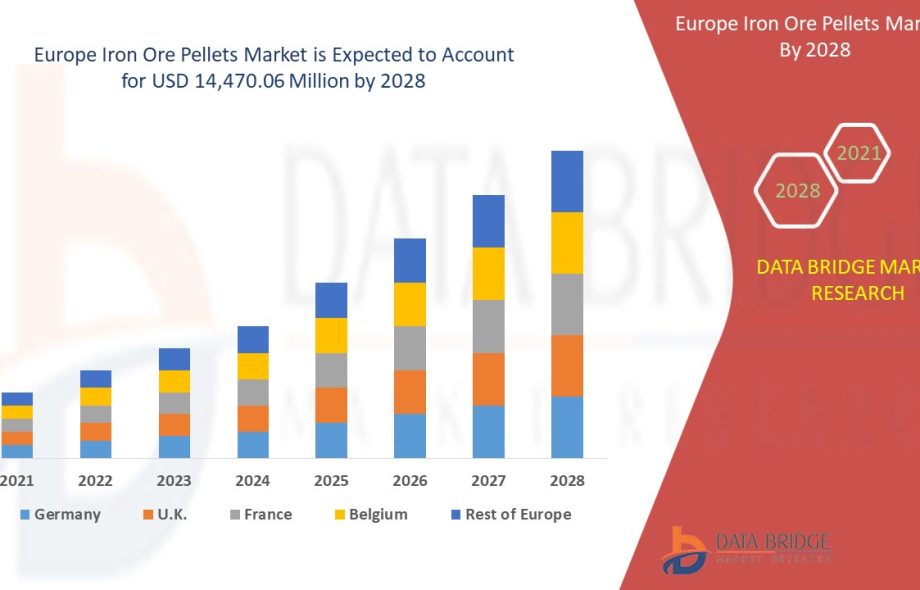

Market Size and Growth Projections

The Europe Iron Ore Pellets Market was valued at USD XX billion in 2024 and is projected to reach USD XX billion by 2032, growing at a CAGR of XX%. This growth is driven by the strong expansion of the steel manufacturing sector, surging construction activities, and advancements in sustainable pellet production technologies. European steelmakers are increasingly investing in low-carbon ironmaking methods, such as hydrogen-based direct reduction, which further boosts pellet consumption.

Key Growth Factors

Rising demand for green and sustainable steel production across Europe.

Increased focus on pellet-based direct reduction iron (DRI) processes to reduce CO₂ emissions.

Growing infrastructure investments in construction, automotive, and industrial manufacturing.

Technological improvements in pelletizing and beneficiation processes enhancing efficiency.

Government support for energy transition and circular economy initiatives.

Market Segmentation

By Type

Hematite Pellets

Magnetite Pellets

Others

By Technology

Blast Furnace (BF) Pellets

Direct Reduction (DR) Pellets

By Application

Steel Production

Iron-based Alloys

Foundries

Others

By End User

Construction Industry

Automotive Industry

Shipbuilding

Heavy Machinery Manufacturing

Others

Regional Insights

Western Europe:

Countries such as Germany, France, and the UK lead the regional market due to the presence of major steel producers, strong industrial infrastructure, and policies promoting low-carbon steel manufacturing.

Northern Europe:

Sweden and Finland are key players with active investments in hydrogen-based ironmaking projects and high-grade iron ore pellet exports, notably through companies like LKAB.

Southern Europe:

Italy and Spain exhibit steady demand driven by the automotive and construction sectors, focusing on efficient and cleaner steelmaking processes.

Eastern Europe:

Poland and Ukraine are emerging as important markets, benefiting from industrial expansion, modernization of steel plants, and the availability of raw materials.

Key Market Drivers

Increasing demand for premium-grade pellets with high Fe content and minimal impurities.

Shift toward hydrogen-based DRI technologies in alignment with EU carbon neutrality goals.

Expansion of renewable energy projects boosting demand for steel components.

Technological innovation in pelletizing equipment and energy recovery systems.

Strategic long-term supply partnerships between mining companies and steel producers.

Market Challenges and Restraints

Volatility in iron ore prices impacting production costs.

High energy consumption in pelletizing and induration processes.

Regulatory challenges linked to carbon emissions and mining permits.

Dependence on imports of high-grade iron ore concentrates.

Supply chain disruptions affecting raw material availability.

Competitive Landscape

The Europe Iron Ore Pellets Market is characterized by the presence of leading mining and metallurgical companies focusing on sustainable production, technological innovation, and regional supply chain resilience.

Key Companies:

LKAB (Luossavaara-Kiirunavaara AB)

Vale S.A.

Ferrexpo PLC

Cleveland-Cliffs Inc.

ArcelorMittal

Rio Tinto Group

Anglo American PLC

Metinvest Group

Severstal PJSC

U.S. Steel Europe

Strategic Developments:

Investments in carbon-neutral pellet plants using renewable energy.

Development of DR-grade pellets optimized for hydrogen-based steelmaking.

Partnerships between iron ore miners and European steelmakers for supply stability.

Research collaborations focusing on alternative binding materials for pellets.

Adoption of automation and digital monitoring for production optimization.

Technological Innovations

Hydrogen-based reduction technologies to replace fossil fuels in pelletizing.

AI and IoT integration for process control and efficiency tracking.

Energy-efficient furnaces and waste heat recovery systems.

Development of carbon-free pellet induration techniques.

Implementation of digital twin technologies for predictive maintenance.

SWOT Analysis

Strengths Weaknesses Opportunities Threats

Strong steel demand across Europe High capital investment in pelletizing plants Adoption of hydrogen-based DRI technology Fluctuating iron ore and energy prices

Focus on sustainability and low emissions Dependence on imported raw materials Government incentives for green steel Competition from alternative materials

Advanced pelletizing technology Environmental regulations and carbon taxes Growing export potential for high-grade pellets Supply chain and geopolitical risks

Future Market Outlook

The Europe Iron Ore Pellets Market is poised for steady growth as steel producers embrace sustainable and low-emission production methods. The shift toward hydrogen-based steelmaking, combined with the region’s strong industrial base and policy support for green technologies, will sustain demand for high-quality pellets. Innovations in process automation and carbon-free production will play a pivotal role in shaping the future of the European steel value chain.

Conclusion

The Europe Iron Ore Pellets Market is at the forefront of Europe’s industrial transformation toward sustainability. With the convergence of technological innovation, green manufacturing, and policy-driven decarbonization, the market is evolving rapidly. Companies focusing on clean production technologies, supply chain efficiency, and high-grade pellet development are expected to lead the next wave of growth in Europe’s dynamic steel ecosystem.

:

: